Fabrication

Our team will fabricate and assemble as many pieces as possible in the shop to minimize additional work on the jobsite.

Committed to excellence.

Investing in technology.

Once the slab photos and CAD drawings created in the Engineering phase are approved, it’s time to cut the stone pieces that will be installed. Not so long ago, cutting stone slabs could be a rather dramatic point in the process. There could be a degree of interpretation or judgment involved. The question some might hesitate to say out loud was

“Would the cut stone live up to the promise of the drawings?”

Today, at Nunzio & Sons, we can unequivocally say “Yes!” Not only do our cut slabs live up to the promise of the drawings, they completely 100% MATCH the drawings! This is because they were literally cut FROM the drawings themselves. That’s the beauty of digital technology, a meticulous process, and a commitment to excellence. The slabs are cut exactly as laid out in the diagrams. There’s no interpretation. There’s no judgment. There’s only faultless execution of the client-approved drawings.

New machinery arriving summer 2021

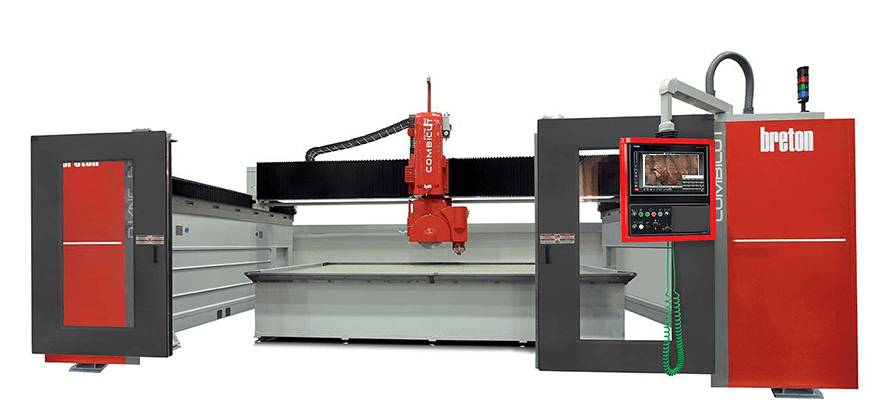

We are excited to be bringing the Breton Combi Sawjet into our fabrication shop this summer. This 5-axis stone cutting machine combines saw and waterjet cutting. The machine handles a variety of complex processes including vertical, inclined, rectilinear and curvilinear cuts.

Detailed cutting work, such as logos and lettering, is typically done by hand or requires being sent out to a third party, costing valuable time. With the CNC waterjet and its leading edge software technology, even the most detailed cutting will be completed with extreme efficiency and exact accuracy.

The Breton Combi Sawjet expands Nunzio and Sons’ inhouse capabilities for detailed cutting work.

Finishing touches

Every piece of natural stone passes through our slab polishing machine for the stone face to be finished according to the client’s request. Here, it’s given a polished, honed, brushed, or antiqued finish. (We can also provide sandblasted, flamed finish, and more.)

Sometimes, the natural veining in one slab might not be quite as aesthetic as in other slabs of the same stone. We have been known to mitigate unsightly natural veining in a slab and inconspicuously fill with a matching epoxy to create the perfect finishing touch.

Fabrication is an art

Our team will fabricate and assemble as many pieces as possible in the shop to minimize additional work on the jobsite.

We pride ourselves with a wonderful group of talented fabricators. They have the hands of true artisans. They complete the fabrication with the highest level of quality and attention to detail.

Receiving slabs in fabrication shop.

Dry Lay Process: Layout stones for a quality check of cutting accuracy & prepare for delivery.

How Can We Help You on Your Next Project?

What is your vision for using stone tiles in your next project? Let’s talk about how procuring the right stone from the right quarry can add great value to the final outcome of your project.

Call STEVEN today to start the conversation!

(631) 467-1011

Contact Us

We guarantee your privacy - your information will not be shared.

Copyright © 2021 Nunzio and Sons